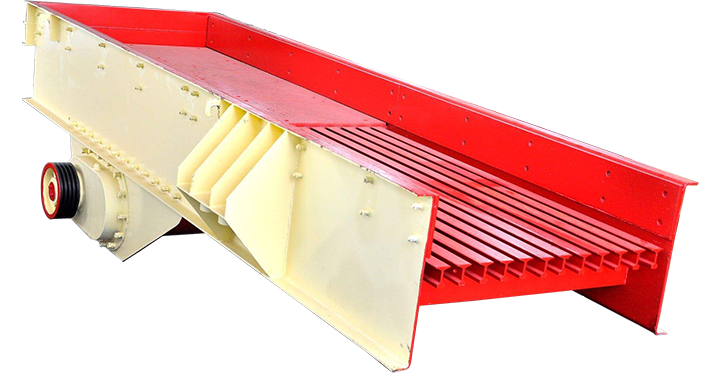

This machine is a feeding device that uses the principle of vibration. Due to its simple structure and easy operation, it is widely used in mineral processing, building materials, silicate and chemical industries. The vibrating feeder can continuously and evenly feed the crusher in the ore production line, effectively avoiding clogging of the crusher inlet.

The vibrating feeder is mainly composed of a vibration frame, a vibrator, a spring, a motor vibrating frame and a motor. The vibrator is composed of two eccentric shafts at specific positions and a pair of meshing gears. During assembly, the two gears must be meshed according to the marks, and the two eccentric shafts are rotated through the motor drive, thereby generating a huge synthetic linear excitation force, which forces the machine body to vibrate on the support spring and uses this vibration as the power to move the material sliding and throwing motions to performed on the trough, thereby moving the material forward to achieve the purpose of feeding. When the materials pass through the screen bars on the tank body, smaller materials can fall through the gaps between the screen bars without going through the next crushing process, thus achieving a screening effect.

選擇語(yǔ)言

選擇語(yǔ)言

Home

Home Product

Product Telephone

Telephone Message

Message